Steam systems represent a critical component in countless industrial operations, where maintaining optimal thermal efficiency directly impacts operational costs and energy consumption. The challenge of preventing valuable steam from escaping while effectively removing condensate has led engineers to develop sophisticated solutions, with the inverted bucket steam trap emerging as one of the most reliable and efficient mechanisms available. This innovative device operates on fundamental thermodynamic principles to create an automated system that distinguishes between steam and condensate, ensuring maximum energy retention while maintaining system integrity across diverse industrial applications.

Understanding the Fundamental Operating Principles

Thermodynamic Foundation of Bucket Technology

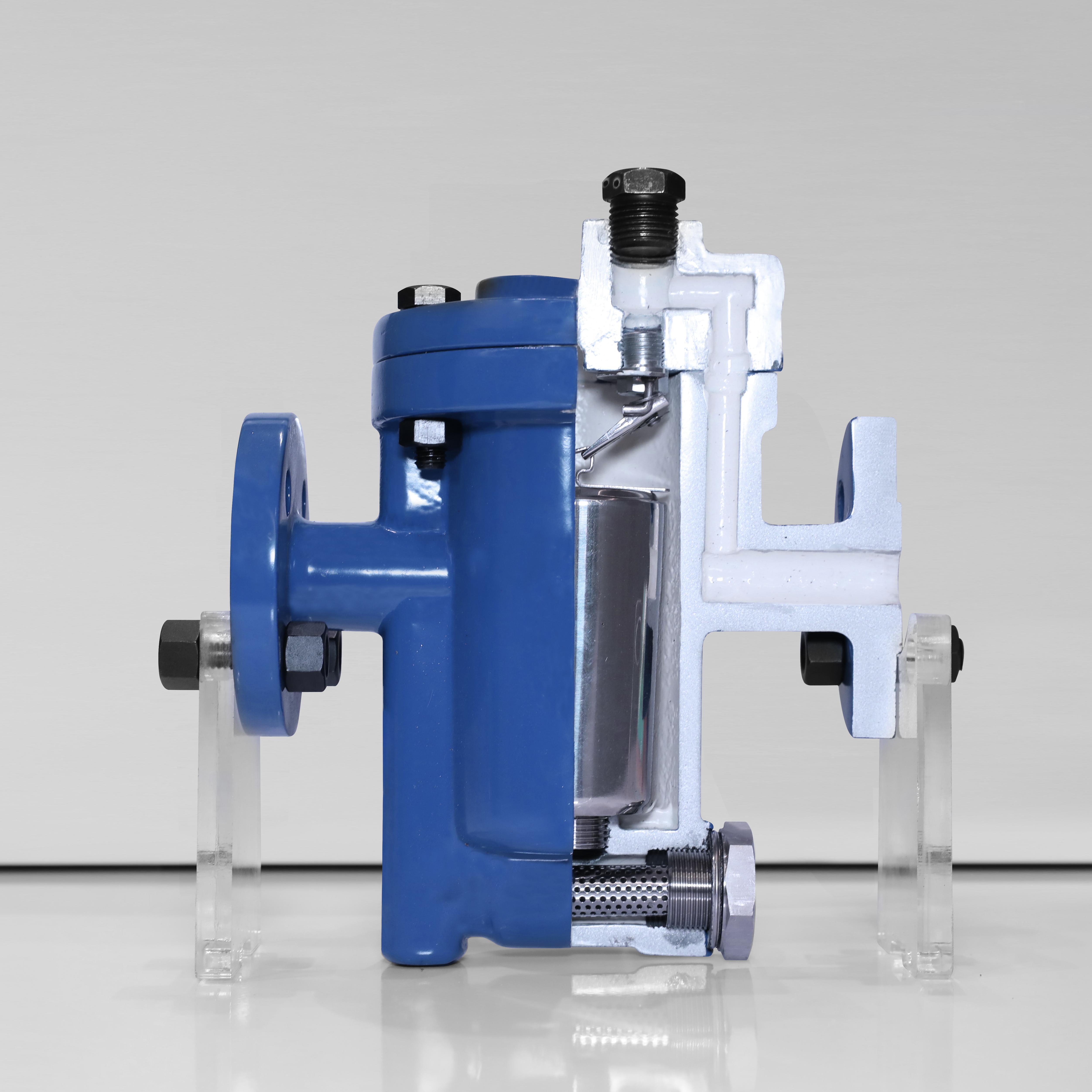

The operational excellence of an inverted bucket steam trap stems from its ingenious exploitation of buoyancy principles and density differentials between steam and liquid condensate. When steam enters the trap chamber, it fills the inverted bucket, causing the mechanism to rise due to steam's significantly lower density compared to water. This upward movement positions the bucket to seal the discharge valve, preventing steam from escaping the system. The mechanism relies on the fundamental physical property that steam occupies approximately 1600 times more volume than the equivalent mass of water at atmospheric pressure.

As condensate accumulates within the trap housing, it displaces the steam inside the bucket through natural density stratification. The heavier condensate gradually fills the bucket from the bottom, forcing the lighter steam out through a small vent hole strategically positioned at the bucket's top. This process continues until sufficient condensate weight overcomes the diminishing buoyancy force, causing the bucket to sink and open the discharge valve. The entire cycle operates without external power sources, making it an inherently reliable and energy-efficient solution for steam system management.

Mechanical Components and Design Integration

The inverted bucket steam trap incorporates several precision-engineered components that work in harmony to achieve consistent performance across varying operational conditions. The central bucket mechanism features a carefully calibrated weight and volume ratio that ensures proper response to condensate levels while maintaining sensitivity to steam presence. The discharge valve assembly utilizes corrosion-resistant materials and precision machining to create reliable sealing surfaces that prevent leakage during extended operational periods.

Supporting infrastructure includes inlet and outlet connections designed to optimize flow patterns and minimize pressure losses throughout the condensate removal process. The trap housing incorporates thermal expansion considerations and pressure rating specifications that accommodate the demanding conditions typical in industrial steam systems. Advanced models feature adjustable components that allow field technicians to fine-tune performance characteristics based on specific application requirements and operational parameters.

Mechanisms for Steam Loss Prevention

Selective Permeability and Vapor Discrimination

The steam loss prevention capabilities of an inverted bucket steam trap result from its ability to maintain distinct separation between vapor and liquid phases throughout the operational cycle. The mechanism creates a dynamic barrier that responds instantaneously to phase changes, ensuring that valuable steam remains within the distribution system while condensate flows freely to collection points. This selective permeability operates continuously without requiring external monitoring or adjustment, providing autonomous protection against energy losses.

The discrimination process relies on the trap's sensitivity to fluid density changes that occur during phase transitions. When steam condenses within the system, the resulting volume reduction creates space for additional condensate accumulation, triggering the bucket mechanism to respond appropriately. This natural feedback loop ensures that the trap remains closed during steam flow periods while opening promptly when condensate requires removal, optimizing energy retention efficiency.

Pressure Differential Management

Effective steam loss prevention requires sophisticated management of pressure differentials across the trap mechanism to ensure proper operation under varying system conditions. The inverted bucket design incorporates pressure balancing features that maintain consistent performance regardless of upstream pressure fluctuations or downstream backpressure conditions. This capability prevents steam blow-through events that commonly occur with less sophisticated trap designs when pressure conditions change rapidly.

The trap mechanism utilizes controlled pressure equalization through strategically positioned ports and chambers that buffer sudden pressure changes while maintaining the fundamental operating principles. Advanced pressure management systems incorporate multiple stages of pressure reduction that prevent cavitation damage and extend component service life while ensuring reliable steam retention performance throughout the operational envelope.

Operational Efficiency and Performance Optimization

Energy Conservation Through Precise Control

The energy conservation benefits of inverted bucket steam trap technology extend beyond simple steam retention to encompass comprehensive thermal efficiency optimization throughout industrial processes. By maintaining precise control over condensate removal timing and volume, these devices ensure that heat recovery systems operate at maximum effectiveness while preventing thermal shock conditions that can damage equipment and reduce system longevity. The consistent operation eliminates energy waste associated with steam leakage and improves overall process stability.

Performance optimization features include self-regulating mechanisms that adjust response characteristics based on condensate load variations and system pressure changes. This adaptive capability ensures optimal performance across diverse operating conditions without requiring manual intervention or complex control systems. The result is sustained energy efficiency that translates directly into reduced operational costs and improved environmental performance for industrial facilities.

Maintenance Requirements and Longevity Factors

The robust construction and simplified mechanical design of inverted bucket steam trap systems contribute to extended service life and reduced maintenance requirements compared to alternative condensate management technologies. The absence of complex electronic components or precision springs eliminates common failure points while the durable materials resist corrosion and wear under demanding industrial conditions. Regular maintenance procedures focus on straightforward inspection and cleaning operations that can be performed by standard maintenance personnel.

Longevity factors include the trap's resistance to contamination from system debris and scale formation, which commonly affect other trap designs. The large internal volume and robust construction accommodate moderate levels of contamination without compromising operational effectiveness, while the simple geometry facilitates thorough cleaning during scheduled maintenance intervals. These characteristics ensure consistent performance over extended operational periods with minimal intervention requirements.

Industrial Applications and Implementation Considerations

Process Industry Integration

Industrial applications for inverted bucket steam trap technology span numerous sectors including chemical processing, petroleum refining, food and beverage production, and pharmaceutical manufacturing. Each application presents unique challenges related to process temperatures, pressures, and contamination levels that require careful consideration during trap selection and installation. The versatility of bucket trap designs allows customization for specific operating conditions while maintaining fundamental performance characteristics.

Implementation considerations include proper sizing calculations based on condensate load projections and system pressure requirements. Installation procedures must account for proper orientation, accessibility for maintenance operations, and integration with existing piping systems. Advanced applications may require specialized materials or coatings to resist aggressive chemical environments or extreme temperature conditions encountered in industrial processes.

System Design and Configuration Options

Modern inverted bucket steam trap installations incorporate sophisticated monitoring and control capabilities that enhance operational visibility and enable predictive maintenance strategies. Configuration options include remote monitoring sensors that track trap performance metrics and alert operators to potential issues before failures occur. These systems integrate with facility management platforms to provide comprehensive oversight of steam system efficiency and identify optimization opportunities.

Design flexibility accommodates various installation constraints including space limitations, piping configurations, and access requirements. Modular designs allow field assembly and customization while standardized interfaces ensure compatibility with existing system components. Advanced configurations incorporate bypass systems and isolation valves that enable maintenance operations without system shutdown, minimizing operational disruptions and improving facility availability.

Performance Advantages Over Alternative Technologies

Comparative Efficiency Analysis

When evaluated against alternative steam trap technologies such as thermostatic and thermodynamic designs, inverted bucket steam trap systems demonstrate superior performance in several critical areas. The mechanical simplicity provides inherent reliability advantages while the responsive operation ensures minimal steam loss during normal operating conditions. Comparative studies indicate significantly lower energy loss rates and extended service intervals compared to competing technologies under similar operating conditions.

Efficiency advantages become particularly pronounced in applications with variable condensate loads or fluctuating pressure conditions where the adaptive response characteristics of bucket traps provide consistent performance. The technology excels in handling large condensate volumes while maintaining precise steam retention, making it ideal for high-capacity industrial applications where energy efficiency directly impacts operational economics.

Reliability and Operational Stability

The operational stability of inverted bucket steam trap systems results from the inherent mechanical design that eliminates dependence on temperature-sensitive components or precise calibration requirements. This characteristic provides consistent performance across wide temperature ranges and varying operating conditions while reducing sensitivity to installation orientation and piping configurations. The robust construction withstands thermal cycling and pressure fluctuations that commonly cause failures in alternative trap designs.

Reliability benefits extend to reduced unplanned maintenance requirements and lower total cost of ownership over the equipment lifecycle. The predictable operation enables accurate maintenance scheduling while the durable construction minimizes replacement part requirements. These factors combine to provide superior operational availability and reduced lifecycle costs for industrial steam systems.

FAQ

How does an inverted bucket steam trap automatically distinguish between steam and condensate?

An inverted bucket steam trap utilizes the fundamental density difference between steam and liquid water to provide automatic discrimination. Steam entering the bucket creates buoyancy that lifts the mechanism and closes the discharge valve, while condensate accumulation gradually fills the bucket from below, reducing buoyancy until the weight causes the bucket to sink and open the valve for condensate discharge.

What maintenance procedures are required to ensure optimal performance of inverted bucket steam traps?

Regular maintenance for inverted bucket steam traps includes periodic inspection of the bucket mechanism for proper movement, cleaning of internal surfaces to remove scale or debris accumulation, verification of valve seating surfaces for wear or damage, and testing of the vent hole to ensure proper steam release. Most systems require annual inspection with cleaning performed as needed based on operating conditions and water quality.

Can inverted bucket steam traps handle varying condensate loads effectively?

Yes, inverted bucket steam traps excel at handling variable condensate loads due to their responsive mechanical design that automatically adjusts to changing conditions. The bucket mechanism responds proportionally to condensate volume, opening wider and for longer periods during high-load conditions while maintaining tight closure during low-load periods, ensuring efficient operation across the full range of typical industrial applications.

What are the typical pressure and temperature limitations for inverted bucket steam trap operation?

Standard inverted bucket steam traps typically operate effectively at pressures up to 600 PSI and temperatures reaching 750°F, though specialized designs can accommodate higher conditions. The specific limitations depend on materials of construction, valve design, and housing specifications, with stainless steel and specialized alloy versions available for extreme service conditions in chemical processing and power generation applications.

Table of Contents

- Understanding the Fundamental Operating Principles

- Mechanisms for Steam Loss Prevention

- Operational Efficiency and Performance Optimization

- Industrial Applications and Implementation Considerations

- Performance Advantages Over Alternative Technologies

-

FAQ

- How does an inverted bucket steam trap automatically distinguish between steam and condensate?

- What maintenance procedures are required to ensure optimal performance of inverted bucket steam traps?

- Can inverted bucket steam traps handle varying condensate loads effectively?

- What are the typical pressure and temperature limitations for inverted bucket steam trap operation?