Steam tracing systems in industrial applications demand components that can withstand extreme conditions while maintaining consistent performance over extended periods. Among the various steam trap technologies available, the inverted bucket steam trap stands out as the most reliable solution for harsh tracing environments. These robust devices have earned their reputation through decades of proven performance in petrochemical plants, refineries, and other demanding industrial settings where failure is not an option.

The unique operating mechanism of inverted bucket steam traps provides several distinct advantages that make them particularly well-suited for challenging applications. Unlike other steam trap designs that rely on temperature-sensitive elements or delicate float mechanisms, these devices utilize a simple yet effective buoyancy principle that remains consistent regardless of ambient conditions. This fundamental reliability becomes crucial when dealing with trace heating systems that must operate continuously in harsh environments where temperature fluctuations, vibrations, and corrosive atmospheres are common challenges.

Industrial facilities worldwide have recognized the superior performance characteristics of inverted bucket steam traps in applications ranging from pipeline freeze protection to process temperature maintenance. The growing demand for energy-efficient steam systems has further highlighted the importance of selecting the right trap technology, as improper steam trap selection can result in significant energy losses, increased maintenance costs, and operational disruptions that impact overall plant productivity.

Understanding the Inverted Bucket Steam Trap Mechanism

Basic Operating Principles and Components

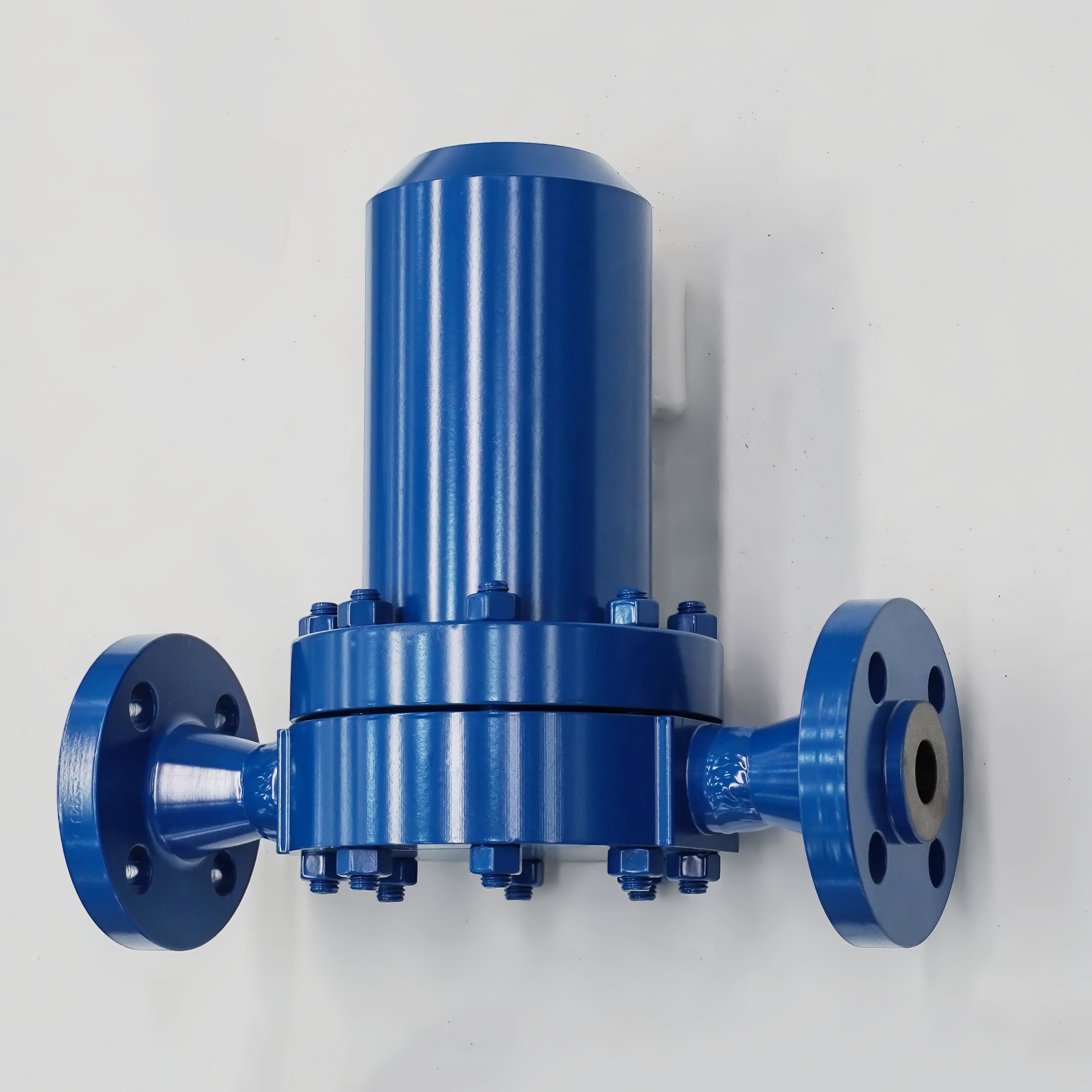

The inverted bucket steam trap operates on a straightforward mechanical principle that eliminates the need for complex temperature-sensitive components. At the heart of the device lies an inverted bucket that moves up and down within the trap body based on the presence of steam or condensate. When steam enters the trap, it fills the inverted bucket and causes it to rise, which closes the valve seat and prevents steam loss. As the steam condenses and condensate accumulates, the bucket loses buoyancy and drops, opening the discharge valve to allow condensate removal.

This mechanical operation relies solely on the physical properties of steam and water density differences, making it inherently reliable across a wide range of operating conditions. The absence of temperature-sensitive elements means that the trap maintains consistent performance regardless of ambient temperature variations, a critical advantage in outdoor installations or environments with extreme temperature swings. The robust construction typically features cast iron or stainless steel bodies with hardened valve seats designed to withstand the repeated opening and closing cycles required in continuous operation.

The internal components of an inverted bucket steam trap are engineered for longevity and minimal maintenance requirements. The bucket itself is typically constructed from corrosion-resistant materials and designed with specific weight and buoyancy characteristics that ensure proper operation across the intended pressure and temperature ranges. The valve seat and disc are manufactured from materials selected for their ability to maintain tight sealing under repeated thermal cycling, preventing steam leakage that would compromise system efficiency.

Advantages Over Alternative Steam Trap Technologies

When compared to thermodynamic and thermostatic steam traps, inverted bucket steam traps demonstrate superior reliability in harsh environments due to their mechanical simplicity and robust construction. Thermodynamic traps, while compact and initially cost-effective, are susceptible to failure in applications with varying loads or in the presence of system vibrations. The disc mechanism in thermodynamic traps can become damaged or wear prematurely when exposed to water hammer or pressure fluctuations common in tracing systems.

Thermostatic steam traps face different challenges in harsh applications, primarily related to the temperature-sensitive elements that control their operation. These elements can drift over time, especially when exposed to superheated steam or rapid temperature changes, leading to improper operation and either steam loss or inadequate condensate removal. The bellows or bimetallic elements used in thermostatic traps are also vulnerable to mechanical damage from system vibrations or water hammer events.

The inverted bucket design eliminates these vulnerability points by relying on fundamental physical principles rather than precision-engineered components that can degrade over time. This inherent reliability translates to longer service intervals, reduced maintenance costs, and improved overall system availability. In critical tracing applications where trap failure could result in process shutdowns or safety hazards, the proven reliability of inverted bucket steam traps provides essential peace of mind for plant operators and maintenance personnel.

Performance Characteristics in Harsh Industrial Environments

Temperature and Pressure Resistance Capabilities

Inverted bucket steam traps excel in applications involving extreme temperature and pressure conditions commonly encountered in industrial tracing systems. These devices are routinely engineered to handle steam pressures ranging from vacuum conditions to several hundred psi, with temperature capabilities extending well beyond the saturation temperatures of most industrial steam systems. The robust mechanical design allows them to maintain proper operation even when subjected to pressure surges or temperature spikes that might damage more delicate trap technologies.

The thermal mass and construction materials of inverted bucket steam traps provide excellent resistance to thermal shock, a common occurrence in steam tracing systems where rapid heating and cooling cycles are routine. The cast iron or steel construction distributes thermal stresses effectively, preventing the cracking or warping that can affect lighter-weight trap designs. This thermal stability ensures consistent performance over the life of the installation, reducing the need for frequent replacements or adjustments.

Field experience in petrochemical and refining applications has demonstrated the ability of inverted bucket steam traps to maintain proper operation in environments where ambient temperatures range from arctic conditions to desert heat. The mechanical operation principle remains unaffected by external temperature variations, unlike thermostatic traps that may require recalibration or adjustment when installed in environments with extreme ambient conditions.

Corrosion and Chemical Resistance Properties

The material selection and construction methods used in inverted bucket steam trap manufacturing provide exceptional resistance to the corrosive environments commonly found in industrial facilities. Standard cast iron bodies offer good resistance to general atmospheric corrosion, while stainless steel versions provide enhanced protection in more aggressive chemical environments. The internal components are typically manufactured from materials specifically chosen for their ability to withstand exposure to condensate that may contain traces of chemicals or treatment additives.

Steam systems in industrial facilities often contain condensate with reduced pH levels due to carbonic acid formation or chemical treatment programs designed to prevent scaling and corrosion in boiler systems. Inverted bucket steam traps are designed to handle these conditions through appropriate material selection and protective coatings where necessary. The larger internal volumes and flow passages in these traps also provide better resistance to fouling from suspended particles or chemical deposits that might clog smaller orifices in other trap designs.

Regular inspection and maintenance practices can further extend the service life of inverted bucket steam traps in corrosive environments. The accessibility of internal components allows for periodic cleaning and replacement of wear parts without requiring complete trap replacement, making them a cost-effective choice for long-term operation in challenging chemical environments.

Installation and Maintenance Advantages

Simplified Installation Requirements

The installation of inverted bucket steam traps in tracing applications offers significant advantages over other trap technologies, primarily due to their tolerance for installation variations and forgiving operational characteristics. Unlike thermodynamic traps that require specific orientation and careful attention to piping configuration, inverted bucket steam traps can accommodate minor installation imperfections without compromising performance. This flexibility reduces installation time and costs while minimizing the potential for installation-related performance issues.

The larger internal capacity of inverted bucket steam traps provides natural surge capacity that helps protect the system from water hammer and pressure fluctuations during startup and operation. This inherent surge protection eliminates the need for additional dampening devices or special startup procedures that may be required with other trap types. The ability to handle varying condensate loads without adjustment makes them ideal for tracing systems where load conditions may change based on ambient weather or process variations.

Piping connections for inverted bucket steam traps are typically straightforward, requiring only standard threaded or flanged connections with appropriate drainage provisions. The robust construction allows for standard pipe wrenching techniques during installation without concern for damaging delicate internal components. This simplicity reduces the skill level required for installation and minimizes the potential for installation errors that could affect long-term performance.

Maintenance Interval Extensions and Cost Benefits

One of the most significant advantages of inverted bucket steam traps in harsh tracing applications is their ability to operate for extended periods without requiring maintenance or adjustment. Field experience consistently shows maintenance intervals measured in years rather than months, compared to other trap technologies that may require frequent attention. This extended service life directly translates to reduced maintenance labor costs and improved system availability.

When maintenance is required, the design of inverted bucket steam traps allows for relatively simple repair procedures that can often be performed without removing the trap from the system. The accessible internal components and standardized replacement parts make maintenance straightforward for plant personnel, reducing dependence on specialized contractors or extended system shutdowns. The availability of repair kits containing commonly replaced components further simplifies maintenance planning and inventory management.

The predictable wear patterns of inverted bucket steam traps enable effective preventive maintenance scheduling based on operating hours or calendar intervals rather than reactive maintenance triggered by failures. This predictability allows maintenance teams to plan outages and parts inventory more effectively, reducing overall maintenance costs and improving system reliability. The robust construction also means that when maintenance is performed, the restored trap typically provides service life comparable to a new unit.

Energy Efficiency and Economic Considerations

Steam Loss Prevention and Energy Conservation

The tight shut-off characteristics of inverted bucket steam traps contribute significantly to energy conservation in steam tracing systems. The mechanical valve design provides positive closure that prevents steam bypass, ensuring that energy is used efficiently for the intended heating application rather than being lost through trap leakage. This tight shut-off capability becomes increasingly important as energy costs rise and environmental regulations require improved energy efficiency in industrial operations.

Studies of steam trap performance in industrial applications consistently show that inverted bucket steam traps maintain their sealing capability longer than other trap types, resulting in sustained energy efficiency over their service life. The gradual wear characteristics of the valve components allow for predictable performance degradation, enabling maintenance teams to schedule repairs before significant energy losses occur. This predictable behavior contrasts with other trap types that may fail suddenly or gradually lose their ability to prevent steam loss.

The ability of inverted bucket steam traps to handle varying loads without adjustment ensures optimal energy utilization across different operating conditions. During periods of low heat demand, the traps continue to operate efficiently without allowing unnecessary steam loss, while during high-demand periods, they provide the capacity needed to remove condensate effectively. This adaptive capability eliminates the energy waste associated with oversized or poorly matched trap selections.

Life Cycle Cost Analysis and Return on Investment

When evaluating steam trap options for harsh tracing applications, a comprehensive life cycle cost analysis typically favors inverted bucket steam traps despite their higher initial cost compared to some alternatives. The extended service life, reduced maintenance requirements, and superior energy efficiency combine to provide lower total cost of ownership over the typical system lifetime. These economic benefits become more pronounced in applications where trap failure could result in production losses or safety hazards.

The reliability of inverted bucket steam traps in harsh environments reduces the risk of unplanned maintenance expenses and production disruptions associated with trap failures. Insurance and risk management considerations often favor the selection of proven, reliable equipment in critical applications, providing additional economic justification beyond direct operating cost comparisons. The documented performance history of these devices in similar applications provides confidence in projected cost savings and reliability improvements.

Return on investment calculations for inverted bucket steam trap installations typically show payback periods of one to three years, depending on energy costs, maintenance labor rates, and the criticality of the application. The combination of energy savings, reduced maintenance costs, and improved system reliability creates multiple value streams that contribute to the overall economic benefit. Long-term facility planning often favors equipment selections that provide stable, predictable operating costs, making inverted bucket steam traps an attractive choice for strategic facility investments.

FAQ

What makes inverted bucket steam traps more suitable for harsh environments than other trap types

Inverted bucket steam traps excel in harsh environments because they operate using simple mechanical principles rather than temperature-sensitive components or delicate mechanisms. Their robust cast iron or steel construction can withstand extreme temperatures, pressure fluctuations, and corrosive atmospheres. The buoyancy-based operation remains consistent regardless of ambient conditions, and the absence of precision-engineered elements that can drift or fail makes them inherently more reliable in challenging industrial settings.

How often do inverted bucket steam traps require maintenance in tracing applications

In properly designed tracing systems, inverted bucket steam traps typically require maintenance every 3-5 years, significantly longer than other trap technologies. The exact interval depends on steam quality, operating conditions, and condensate chemistry. Their robust construction and simple mechanical operation minimize wear, and when maintenance is needed, it often involves only valve seat refurbishment or bucket replacement rather than complete trap replacement.

Can inverted bucket steam traps handle varying loads in steam tracing systems

Yes, inverted bucket steam traps are excellent at handling varying condensate loads without requiring adjustment or recalibration. Their mechanical operation automatically adapts to different flow rates, making them ideal for tracing systems where heat demand changes due to ambient conditions or process variations. The larger internal capacity provides natural surge protection and accommodates load variations that might cause other trap types to malfunction or operate inefficiently.

What are the energy efficiency benefits of using inverted bucket steam traps in tracing applications

Inverted bucket steam traps provide superior energy efficiency through their tight shut-off characteristics that prevent steam loss when condensate removal is not needed. They maintain their sealing capability longer than other trap types, ensuring sustained energy savings over their service life. The ability to operate efficiently across varying load conditions without steam bypass or inadequate condensate removal makes them particularly effective at minimizing energy waste in fluctuating tracing applications.

Table of Contents

- Understanding the Inverted Bucket Steam Trap Mechanism

- Performance Characteristics in Harsh Industrial Environments

- Installation and Maintenance Advantages

- Energy Efficiency and Economic Considerations

-

FAQ

- What makes inverted bucket steam traps more suitable for harsh environments than other trap types

- How often do inverted bucket steam traps require maintenance in tracing applications

- Can inverted bucket steam traps handle varying loads in steam tracing systems

- What are the energy efficiency benefits of using inverted bucket steam traps in tracing applications