Industrial steam systems often encounter challenging conditions where contaminated or dirty steam carries particles, scale, and other debris that can compromise equipment performance. In these demanding environments, selecting the right steam trap becomes critical for maintaining efficient operations and preventing costly downtime. The inverted bucket steam trap stands out as an exceptionally reliable solution specifically engineered to handle dirty steam applications where other trap designs might fail or require frequent maintenance.

The unique operating mechanism of these specialized traps makes them particularly well-suited for environments where steam quality is compromised by dirt, rust particles, pipe scale, and other contaminants. Unlike other steam trap technologies that rely on precise tolerances or small orifices, the inverted bucket design provides robust performance even when dealing with debris-laden condensate. This inherent tolerance to contamination has made inverted bucket steam traps the preferred choice in industries such as petrochemicals, power generation, and heavy manufacturing where steam purity cannot always be guaranteed.

Understanding the specific advantages and operational principles of inverted bucket steam traps helps facility managers and engineers make informed decisions when designing steam distribution systems for challenging industrial environments. The ability to maintain consistent performance while handling dirty steam translates directly into improved system reliability, reduced maintenance costs, and enhanced overall operational efficiency across various industrial applications.

Fundamental Design Principles

Mechanical Operating Mechanism

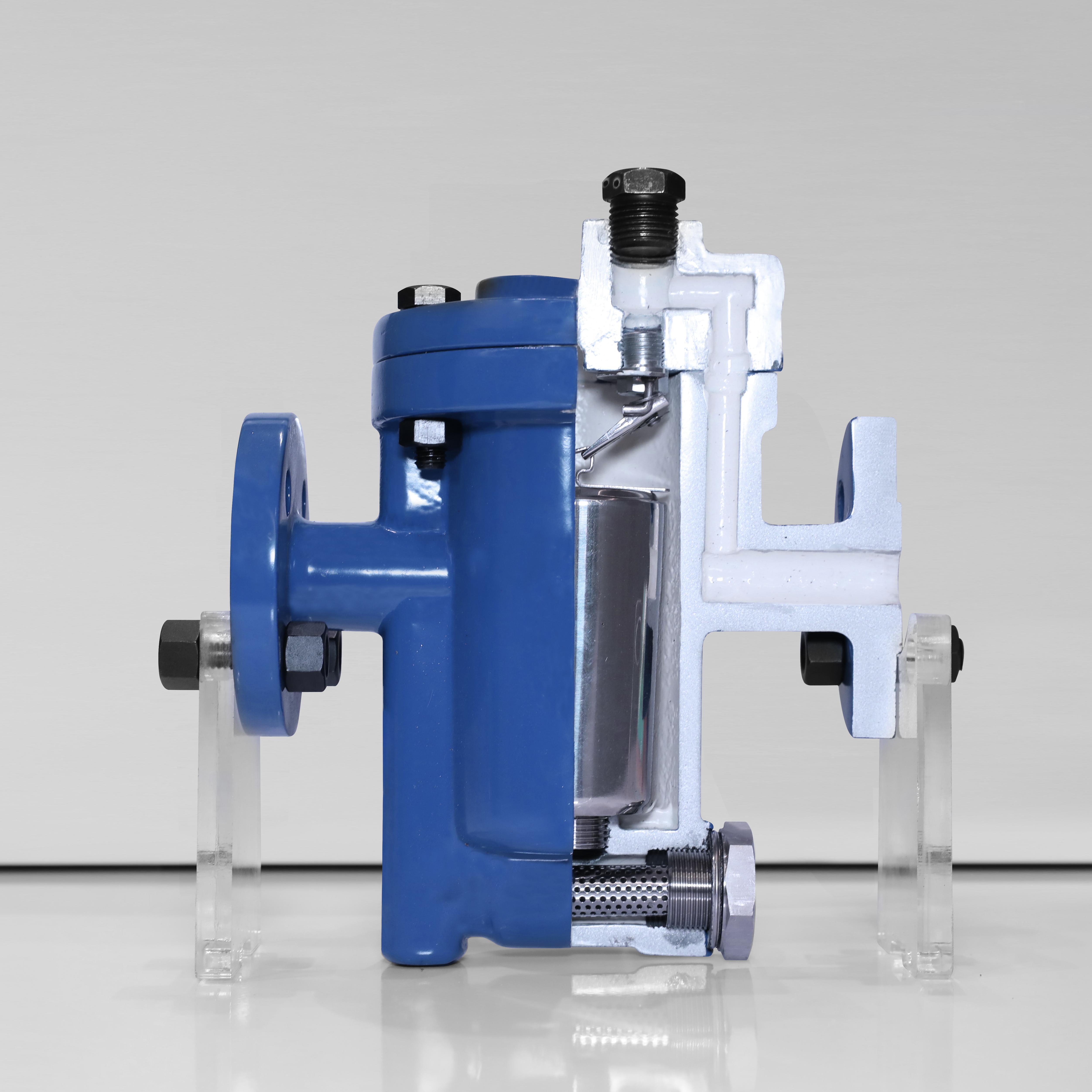

The inverted bucket steam trap operates on a straightforward mechanical principle that relies on the density difference between steam and condensate rather than precise thermal or thermodynamic responses. At the heart of the system lies an inverted bucket that floats on condensate while remaining submerged when steam is present. This bucket connects to a valve mechanism through a simple lever system, creating a direct mechanical linkage that eliminates the need for complex internal components or tight manufacturing tolerances.

When condensate enters the trap body, it causes the inverted bucket to rise, which in turn opens the discharge valve through the connected lever mechanism. As steam enters the bucket space, it displaces the condensate and causes the bucket to sink, closing the valve and preventing steam loss. This mechanical operation continues cyclically, providing automatic and reliable condensate removal without requiring external power or sophisticated control systems.

The simplicity of this mechanical design contributes significantly to the trap's ability to handle contaminated steam conditions. Unlike thermostatic traps that depend on temperature-sensitive elements or thermodynamic traps that require precise orifice dimensions, the inverted bucket mechanism functions effectively even when dirt and debris interfere with normal operation. The robust construction and generous internal clearances accommodate particle contamination that would typically cause other trap types to malfunction or stick in either open or closed positions.

Structural Durability Features

The construction of an inverted bucket steam trap incorporates several design elements that enhance its durability and resistance to contamination-related wear. The trap body typically features thick walls and reinforced connection points to withstand the mechanical stresses associated with frequent cycling under varying pressure conditions. Internal components are manufactured from corrosion-resistant materials such as stainless steel or specialized alloys that maintain their integrity when exposed to aggressive condensate chemistry.

The bucket itself is designed with sufficient wall thickness and structural reinforcement to resist deformation from pressure fluctuations and mechanical impacts from debris carried in the steam flow. Strategic placement of wear-resistant surfaces at contact points between moving components ensures long-term operational reliability even when abrasive particles are present in the system. These durability features translate into extended service intervals and reduced maintenance requirements compared to more delicate trap designs.

Manufacturing precision focuses on maintaining proper clearances and surface finishes that promote smooth operation while accommodating the inevitable accumulation of scale and debris over time. The valve seat and disc assembly incorporates materials and geometric designs that resist scoring and pitting from contaminated condensate, ensuring reliable sealing performance throughout the trap's operational life.

Contamination Handling Capabilities

Dirt and Debris Tolerance

One of the most significant advantages of inverted bucket steam traps in dirty steam applications is their exceptional tolerance to solid contaminants that would quickly disable other trap technologies. The relatively large internal passages and generous clearances between moving parts allow particles of considerable size to pass through the trap without causing jamming or operational interference. This design characteristic makes inverted bucket traps particularly valuable in systems where steam lines cannot be adequately filtered or where upstream equipment generates ongoing contamination.

The trap's ability to handle dirt and debris stems from its mechanical operating principle, which does not rely on small orifices or precise fits between components. While thermodynamic traps can become blocked by particles as small as a few millimeters, and thermostatic elements can be damaged by abrasive materials, the inverted bucket mechanism continues functioning effectively even when significant contamination is present. This tolerance extends to various types of debris including rust scale, pipe joint compound, welding slag, and organic materials that may enter the steam system during startup or maintenance activities.

Field experience demonstrates that inverted bucket steam traps can operate successfully in environments where other trap types require weekly or even daily cleaning to maintain functionality. The self-clearing action of the condensate flow helps sweep accumulated debris through the trap discharge, preventing the buildup that commonly plagues alternative designs. This characteristic significantly reduces maintenance requirements and improves overall system availability in challenging industrial environments.

Scale and Corrosion Resistance

Industrial steam systems frequently encounter scale formation and corrosion products that can severely impact equipment performance and longevity. Inverted bucket steam traps demonstrate superior resistance to these conditions through both their material selection and operational characteristics. The larger internal dimensions and smooth flow paths minimize locations where scale can accumulate and create operational problems, while the mechanical cycling action helps prevent the buildup of deposits that could interfere with proper valve operation.

The materials used in inverted bucket trap construction are specifically chosen for their resistance to the corrosive environments commonly found in dirty steam applications. Stainless steel components resist both general corrosion and localized attack from aggressive condensate chemistry, while specialized coatings and treatments can be applied to further enhance corrosion resistance in particularly challenging applications. These material choices ensure that the trap maintains its structural integrity and operational performance even when exposed to acidic condensate or other corrosive conditions.

Regular condensate discharge through the trap helps flush away scale-forming materials before they can accumulate to problematic levels. The relatively high flow velocities during discharge cycles create turbulent conditions that discourage scale adhesion to internal surfaces. When scale does form, the mechanical operation of the bucket and valve assembly tends to break away loose deposits, preventing the gradual restriction of flow passages that commonly affects other trap designs in similar applications.

Performance Advantages in Harsh Conditions

Reliability Under Variable Loads

Industrial processes often subject steam systems to wide variations in load conditions, creating challenging operating environments where equipment reliability becomes paramount. Inverted bucket steam traps excel in these variable load situations because their mechanical operating principle remains consistent regardless of flow rate variations or pressure fluctuations. Unlike some trap technologies that may become unstable or inefficient under changing conditions, the inverted bucket mechanism maintains reliable condensate removal across the full range of typical industrial operating conditions.

The trap's ability to handle load variations effectively stems from its fundamental design, which automatically adjusts to different condensate flow rates without requiring external control or adjustment mechanisms. During high-load periods with increased condensate production, the trap responds by cycling more frequently while maintaining proper steam retention. Conversely, during low-load conditions with minimal condensate formation, the trap remains closed to prevent steam loss while ready to respond immediately when condensate arrives.

This automatic load-following capability proves particularly valuable in dirty steam applications where other operational challenges already stress the system. Facility operators can rely on consistent trap performance without the need for frequent adjustments or specialized control systems that might be compromised by contamination. The resulting operational stability contributes to improved process efficiency and reduced maintenance requirements across the entire steam distribution system.

Maintenance Accessibility

Maintenance considerations become especially important in dirty steam applications where equipment may require more frequent servicing due to contamination effects. Inverted bucket steam traps are designed with maintenance accessibility in mind, featuring construction that allows for relatively straightforward inspection and service without requiring specialized tools or extensive system shutdown. The trap body typically incorporates removable covers or access ports that permit visual inspection of internal components and cleaning when necessary.

The mechanical simplicity of the inverted bucket design translates into maintenance procedures that can be performed by standard plant maintenance personnel without requiring specialized training or equipment. Component replacement, when needed, involves straightforward mechanical procedures rather than the precise adjustments or calibrations required by some alternative trap technologies. This maintenance simplicity becomes particularly valuable when contamination necessitates more frequent service intervals.

Diagnostic capabilities built into modern inverted bucket steam traps enable maintenance personnel to assess trap condition and performance without disassembly. External indicators or test ports allow for quick verification of proper operation, helping maintenance teams prioritize their efforts and schedule service activities efficiently. These features reduce both the time and cost associated with maintaining steam trap performance in contaminated environments.

Industrial Applications and Use Cases

Petrochemical Industry Applications

The petrochemical industry presents some of the most challenging environments for steam system equipment, with processes that generate significant contamination and operate under demanding conditions. Inverted bucket steam traps have proven exceptionally well-suited for these applications, particularly in process heating systems, distillation column reboilers, and heat exchanger services where steam quality may be compromised by process upsets or equipment limitations. The robust construction and contamination tolerance of these traps make them ideal for maintaining reliable operation in refineries and chemical plants.

In petrochemical applications, steam systems often encounter hydrocarbon contamination, scale formation from hard water, and corrosive conditions from process chemicals. Inverted bucket steam traps handle these challenges effectively while maintaining the precise temperature control required for many chemical processes. Their ability to operate reliably without frequent maintenance reduces the need for process shutdowns and contributes to improved overall plant availability and profitability.

Specific applications within petrochemical facilities include crude oil heating systems, reactor temperature control, and product purification processes where consistent steam trap performance is essential for product quality and safety. The long service life and predictable maintenance requirements of inverted bucket steam traps help plant operators maintain stable operations while managing the complexity of modern petrochemical processes.

Power Generation Facilities

Power generation facilities, particularly those burning solid fuels like coal or biomass, create steam system environments with high levels of contamination from fly ash, scale, and other combustion byproducts. Inverted bucket steam traps serve critical roles in these facilities, handling condensate removal from steam heating systems, fuel preparation equipment, and auxiliary systems that support power plant operations. Their ability to function reliably despite contamination helps ensure continuous power generation and reduces the risk of unplanned outages.

The cycling nature of power plant operations subjects steam systems to frequent startup and shutdown conditions that can introduce additional contamination and stress equipment beyond normal operating parameters. Inverted bucket steam traps accommodate these challenging conditions while maintaining the reliability required for critical power generation infrastructure. Their mechanical robustness ensures continued operation even when other plant systems experience upsets or maintenance issues that might compromise steam quality.

Modern power plants increasingly incorporate environmental control systems and efficiency improvements that can affect steam system cleanliness and operating conditions. Inverted bucket steam traps adapt well to these evolving requirements while providing the long-term reliability needed to support changing plant configurations and operating strategies throughout the facility's operational life.

FAQ

How does an inverted bucket steam trap differ from other steam trap types in dirty steam applications

Inverted bucket steam traps use a mechanical operating principle based on density differences rather than temperature or pressure differentials, making them inherently more tolerant of contamination. Unlike thermostatic traps that rely on temperature-sensitive elements that can be damaged by debris, or thermodynamic traps that depend on precise orifices that can become blocked, inverted bucket traps operate with generous clearances and robust mechanical components that continue functioning even when dirt and scale are present in the system.

What maintenance considerations are important for inverted bucket steam traps in contaminated environments

While inverted bucket steam traps are more tolerant of contamination than other designs, regular inspection of discharge lines and internal components helps ensure optimal performance. Maintenance should focus on checking for scale buildup around the valve seat, ensuring proper bucket movement, and verifying that discharge lines remain clear. The mechanical simplicity of these traps typically allows for straightforward cleaning and component replacement when necessary, usually requiring less frequent service than alternative trap technologies in similar conditions.

Can inverted bucket steam traps handle both light and heavy contamination levels effectively

Yes, inverted bucket steam traps are designed to accommodate varying levels of contamination from light dust and scale to heavier debris loads that might include pipe scale, rust particles, and other solid materials. The trap's large internal passages and mechanical operating mechanism provide consistent performance across different contamination levels, though extremely heavy contamination may require more frequent maintenance intervals to maintain optimal efficiency.

What factors should be considered when selecting an inverted bucket steam trap for dirty steam service

Key selection factors include the expected level and type of contamination, operating pressure and temperature ranges, condensate load variations, and maintenance accessibility requirements. Material selection becomes particularly important, with stainless steel or specialty alloy construction recommended for corrosive environments. Sizing should account for both normal condensate loads and the potential for reduced efficiency due to contamination effects, ensuring adequate capacity under all operating conditions.

Table of Contents

- Fundamental Design Principles

- Contamination Handling Capabilities

- Performance Advantages in Harsh Conditions

- Industrial Applications and Use Cases

-

FAQ

- How does an inverted bucket steam trap differ from other steam trap types in dirty steam applications

- What maintenance considerations are important for inverted bucket steam traps in contaminated environments

- Can inverted bucket steam traps handle both light and heavy contamination levels effectively

- What factors should be considered when selecting an inverted bucket steam trap for dirty steam service